Using advanced bicomponent spinning technology, two polymer melts with different melting points, viscosities, and mechanical properties are separately injected through specially designed spinning components to form various composite structures such as core-sheath, side-by-side, and sea-island types during the spinning process. For example, in the core-sheath structure, the outer layer (sheath) can endow the nonwoven fabric with good wear resistance, antistatic properties, or hydrophilicity, while the inner layer (core) provides basic mechanical properties such as high strength and high elasticity, achieving precise performance matching and optimization. This composite structure is not a simple physical mixture but forms a synergistic effect through intermolecular interactions, leading to a qualitative improvement in the comprehensive performance of the nonwoven fabric.

Using advanced bicomponent spinning technology, two polymer melts with different melting points, viscosities, and mechanical properties are separately injected through specially designed spinning components to form various composite structures such as core-sheath, side-by-side, and sea-island types during the spinning process. For example, in the core-sheath structure, the outer layer (sheath) can endow the nonwoven fabric with good wear resistance, antistatic properties, or hydrophilicity, while the inner layer (core) provides basic mechanical properties such as high strength and high elasticity, achieving precise performance matching and optimization. This composite structure is not a simple physical mixture but forms a synergistic effect through intermolecular interactions, leading to a qualitative improvement in the comprehensive performance of the nonwoven fabric.

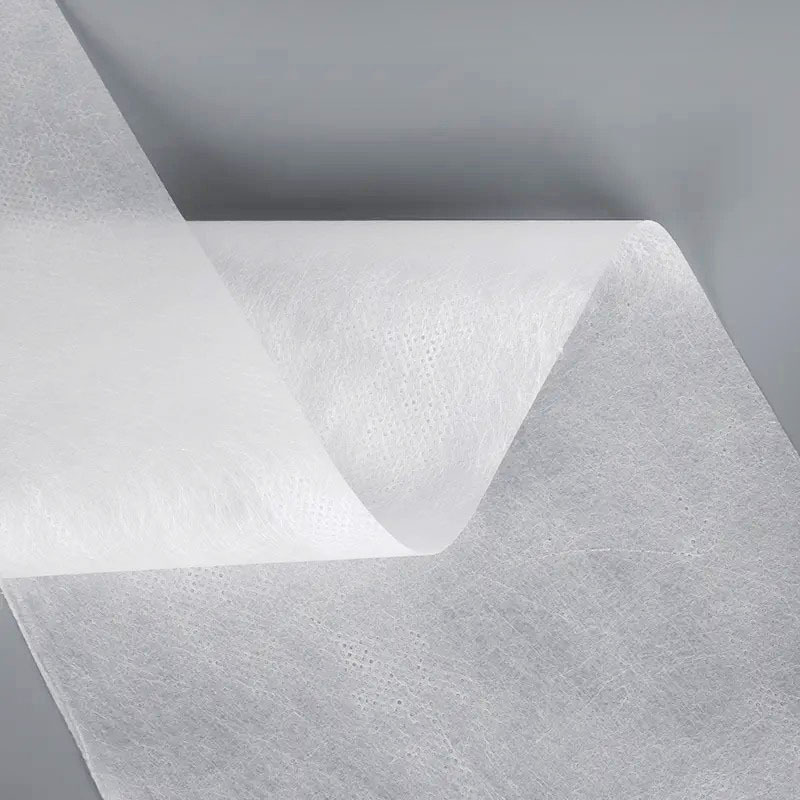

Bicomponent nonwoven materials combine the advantages of both components, showing excellent mechanical indicators such as tensile strength, elongation at break, and tear strength. They also demonstrate significant improvement in the balance of mechanical properties between the longitudinal and transverse directions.

According to different application requirements, functions such as antistatic, antibacterial, waterproof and breathable can be achieved, which greatly expands the application scope of nonwovens.

Bicomponent nonwoven materials also exhibit unique advantages in environmental protection. The degradable polymers can gradually degrade in natural environments, reducing white pollution. They can be recycled and reused to achieve circular utilization of resources, in line with the development trend of green manufacturing.

Medical and Healthcare Field

It can be used to produce surgical gowns, surgical drapes, sterilization bags, as well as daily medical supplies such as masks, bandages, and cotton balls, meeting diverse medical needs.

Personal Care Field

With its soft and comfortable handfeel, good hygroscopicity, and breathability, bicomponent nonwoven materials have become the core material for baby diapers, adult incontinence products, feminine hygiene products, etc. They are also used to manufacture personal care items such as wet wipes and cosmetic cotton pads, catering to people's pursuit of high-quality living.

Packaging Field

Applied in food packaging, such as tea bags and coffee bean bags, it can also be used to produce cargo pallet wrapping cloth, container lining cloth, electronic product packaging bags, etc., effectively protecting goods from damage during transportation and storage.

Automotive Field

Bicomponent nonwoven materials are widely used in interior and functional components, such as automotive seat fabrics, headliner lining cloth, carpets, etc. They are characterized by softness and comfort, wear and dirt resistance, and easy cleaning.

Customization Services

Complimentary samples provided. Supports personalized customization of gram weight, width, and functional coatings (e.g., anti-static/flame retardant) to match specialized application requirements.

Comprehensive Certifications

Company holds ISO 9001, ISO 13485 quality management system certifications, along with FDA and CE compliance certifications.