Melt-blown nonwoven fabric is an innovative synthetic fiber nonwoven material produced using the melt-blowing process, belonging to the field of polymer materials. Our company offers China meltblown nonwoven fabric for sale, made primarily from polypropylene (PP), which undergoes high-temperature melting, high-speed fiber extrusion, cooling, and web formation to create a nonwoven fabric with a unique microstructural arrangement.

Meltblown nonwoven fabric features ultra-fine fibers with diameters typically ranging from 1–5 micrometers (approximately 1/20–1/30 the thickness of a human hair), forming a fluffy, highly porous, and densely interwoven 3D network structure. This unique microstructure has driven strong demand in the global melt blown fabric market, endowing the material with the following core properties:

High Breathability: The abundant inter-fiber voids allow free air circulation, making it ideal for applications requiring high air permeability (e.g., outer layers of masks).

High-Efficiency Filtration: The large specific surface area of ultrafine fibers enables effective capture of microscopic particles such as bacteria, viruses, and dust (filtration efficiency can exceed 95%), which is a key reason why china meltblown nonwoven fabric for sale is widely used in medical and industrial filtration sectors.

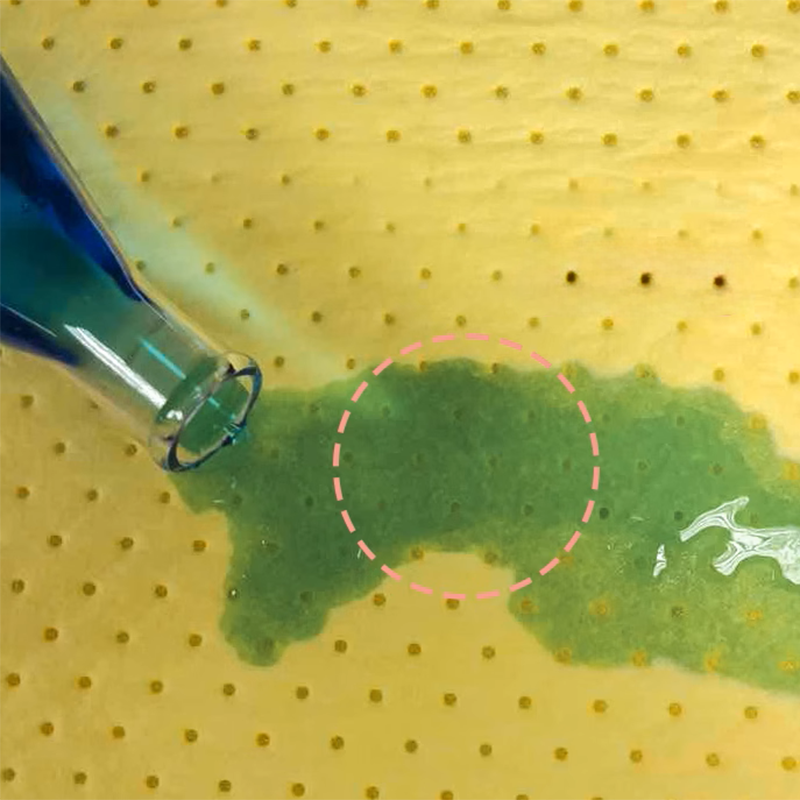

Strong Adsorption Capacity: The capillary action of the fiber surface facilitates rapid liquid absorption (e.g., oils, droplets), suitable for environmental and medical adsorption applications.

Low Air Resistance & High Dust-Holding Capacity: The fluffy and soft fiber structure minimizes airflow resistance while retaining more particulate matter, extending service life.

Electrical Insulation: Polypropylene (PP) is inherently insulating, making it suitable for electronic and electrical protective applications.

Chemical Resistance: Exhibits tolerance to acids, alkalis, and other chemicals, ideal for industrial filtration or specialized environmental protection.

Lightweight & Flexible: The material is thin, lightweight, and easily moldable, supporting diverse product designs.

Core Role in Filtration Performance: In mask production, meltblown nonwoven fabric serves as the critical filtration layer (M layer). Its filtration efficiency directly determines the protective grade of masks (e.g., N95, KN95).

Balancing Eco-Friendliness and Efficiency: Compared to traditional filtration materials (e.g., filter paper, spunbond fabric), meltblown nonwoven combines lightweight properties, cost-effectiveness and customizable features, meeting modern industry's dual demands for both environmental protection and efficiency.

Medical and Hygiene Applications: As a trusted medical fabric material, it is widely used in medical masks, protective clothing, surgical gowns, and disinfecting wipes, fully utilizing its filtration and barrier properties.

Air Purification: Household air purifier filters, automotive AC filters, and industrial dust removal filter materials.

Environmental Protection: Oil-absorbent felts (for marine oil spills and industrial leaks), water treatment filtration materials.

Consumer Products: Thermal lining for cold-weather apparel (e.g., winter coats, thermal masks), absorbent layers in baby diapers, cosmetic cotton pads.

Industrial Manufacturing: Dust-proof packaging for electronic components, battery separators, sound insulation materials.

Advanced Manufacturing Process & Premium Raw Materials

Utilizing cutting-edge production technology and high-quality base materials.

Comprehensive & Rigorous Quality Control System

Implementing a complete and strictly enforced quality management framework.

State-of-the-Art Production Facilities with Strong Capacity Advantages

Equipped with advanced manufacturing equipment and significant production capacity.

Customer-Centric Approach with Full-Scale Professional Services

We maintain a client-focused philosophy, delivering comprehensive professional support.

Exceptional Filtration Performance Exceeding Industry Standards

Achieves >99.9% filtration efficiency for 0.3μm particles, far surpassing industry requirements.