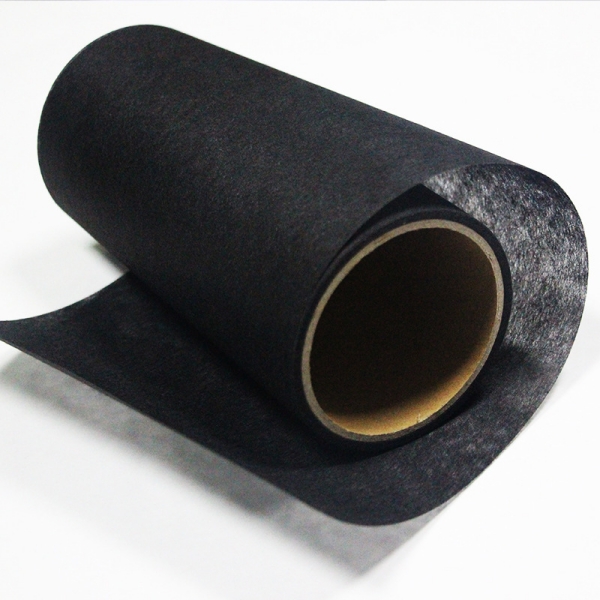

Impregnated non-woven fabric is a non-woven material formed by consolidating fibers through chemical adhesives. Its core process involves applying chemical adhesives (such as emulsion-type, powder-type, or foam-type adhesives) to the fiber web, followed by curing (e.g., hot air drying) to bond the fibers and form a stable network structure.

Compared with other non-woven fabrics (such as spunbond, meltblown, spunlace, etc.), impregnated non-woven fabrics feature low cost, flexible processing, and strong adjustability, making them widely used in medical and healthcare, filtration materials, household products, and other fields.

With their low cost, process flexibility, and functional tunability, impregnated non-woven fabrics occupy an important position in medical, hygiene, industrial, and other sectors. In the future, with the improvement of environmental requirements, the application of biobased fibers and green adhesives will further promote the development of this technology.

Process Flexibility

Adjustable types and contents of adhesives to meet different performance requirements.

Capable of combining multiple fibers to optimize material properties.

Customizable Functions

Endows special functions by adding additives (such as silver-ion antibacterial agents, flame retardants).

Can produce ultra-soft materials (for hygiene products) or high-strength materials (for industrial use).

Environmental Adaptability

Can use biobased adhesives (such as starch glue) or degradable fibers.

Some processes (such as foam impregnation) reduce chemical and energy consumption.

Medical and Healthcare Field

Medical dressings, surgical towels: Soft, hypoallergenic, and sterilizable.

Absorbent layers for sanitary napkins and diapers: High liquid absorbency, breathable, and comfortable.

Disinfectant wipes: Made of wood pulp + viscose fibers, with an obvious degradable trend.

Household and Cleaning Products

Wiping cloths: High bulkiness and strong liquid absorbency (e.g., kitchen paper, industrial rags).

Wall coverings, furniture linings: Can be treated for flame retardancy and mildew resistance.

Industrial Applications

Filtration materials: PET-based chemical bonded non-woven fabrics for air/liquid filtration.

Automotive interiors: Soundproof, heat-insulating, and lightweight.

Packaging materials: Cushioning, moisture-proof, replacing foam plastics.

Agriculture and Horticulture

Seedling cloths: Breathable, water-retaining, and degradable.

Agricultural films: Partially replacing plastic mulch films to reduce pollution.

Diversified Customization: Provide perfect tailor-made solutions according to different customers' needs.

Environmental Material Standards: Produced with 100% virgin materials, no recycled materials added.

Product Versatility: Meet diversified needs for softness, strength, and functionality across industries.

Quality Assurance: The company holds ISO9001 and ISO13485 quality system certifications, as well as FDA and CE certifications.