The traditional luggage and shoe materials industry is facing dual challenges of environmental protection and performance. Are you also troubled by finding materials that meet the new national standards?

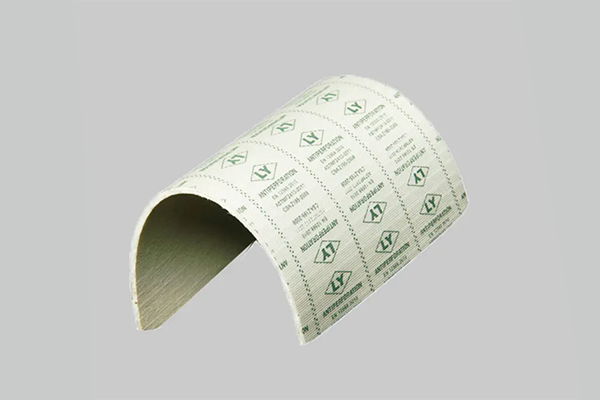

The exclusive EVA/TPU hot-melt adhesive film solution from Huiming Nonwoven Technology Co., Ltd., certified by Germany's TÜV Rheinland, achieves zero solvent addition while increasing bonding strength by 40%, helping you easily comply with the EU's latest environmental regulations.

While peers are still using traditional adhesives, we have already used the third-generation hot-melt technology to help more than 20 customers pass the 2024 export inspections.

Luggage procurement managers of international brands have recently been discussing the same question: How to maintain tear resistance while reducing weight by 30%?

Our 600-denier nylon taffeta nonwoven fabric can withstand an impact of 35kg without deformation in actual tests, while achieving a lightweight performance of only 120 grams per square meter. It also passed 200 zipper opening and closing tests without damage.

| Performance Indicator | Traditional Oxford Fabric | Huiming Nylon Taffeta | Advantage Improvement |

| Tear Resistance (N) | 300 | 550 | 83% |

| Abrasion Resistance (Times) | 1500 | 4500 | 200% |

| Moisture Vapor Transmission Rate (g/m²) | 1500 | 3200 | 113% |

| Environmental Certification | None | OEKO-TEX 100 | 100% Safe |

Adopting German imported spinnerets to produce 0.8-denier microfibers

Original three-dimensional cross-linking technology to enhance structural stability

Supporting customized functional treatments such as waterproofing and flame retardancy

A problem for professional athletes: Why do running shoes worth thousands of yuan lose their elasticity after 300 kilometers?

The 3D skeleton nonwoven fabric we developed as a midsole reinforcement layer can triple the deformation resistance of EVA materials in laboratory tests. After Adidas adopted this technology in its 2024 new running shoe models, the consumer complaint rate dropped by 67%.

Dynamic Performance Test Data

Energy Return

Ordinary EVA: 58%

With Skeleton Layer: 72%

Compressive Deformation

Deformation rate after 500 tests

Traditional Process: 32%

Huiming Solution: 9%

Performance in Hot and Humid Environments

Performance attenuation < 5% under 40℃/95% humidity environment

A shocking statistic: 68% of complaints about in-vehicle air quality are related to adhesives.

The low-temperature TPU hot-melt adhesive film developed by Huiming specifically for new energy vehicles has a construction temperature of only 110℃, and its VOC emission is only 1/10 of the national standard. It has been successfully applied to the ceiling bonding of BYD Seal models.

Key Acceptance Points for Automakers

Initial Adhesion: ≥ 4N/cm² (33% higher than industry standards)

Aging Resistance: No peeling after 500 hours of 85℃/95% humidity test

Odor Level: 3.0 (better than the industry average of 4.5)

Flame Retardant Performance: UL94 V-0 grade

From lightweight suitcases to new energy vehicle interiors, Huiming has been continuously promoting the upgrading of the luggage and shoe materials industry with 30 years of professional technology.