Medical fabrics are an indispensable part of the modern healthcare system. They directly affect patient recovery experience and the operational efficiency of healthcare personnel. With advancements in medical technology, the requirements for medical fabrics have also been rising. Medical fabrics are textile materials made using special processes; they have characteristics such as sterility, breathability, and durability, and are widely used in wound care, surgical protection, and medical packaging. The medical fabrics produced by Guangdong Huiming Nonwoven Technology Co., Ltd. are FDA/ISO certified, providing safe and reliable solutions for medical institutions.

From operating rooms to home care, medical fabrics accompany every stage of medical activities. High-quality medical fabrics not only improve medical quality but also reduce infection risks and enhance patient experience.

Hospitals deal with various high-risk medical scenarios daily. Unqualified medical materials can lead to serious consequences.Certification of medical fabrics is a crucial guarantee of product safety. FDA certification indicates that the product meets the standards of the U.S. Food and Drug Administration, whereas ISO certification means it meets the requirements of the International Organization for Standardization. All medical fabrics by Guangdong Huiming have passed these authoritative certifications.

Let's dive deeper into the significance of medical fabric certification:

Biocompatibility: Ensures materials do not cause rejection reactions in the human body

Antibacterial Performance: Effectively blocks bacteria and viruses

Physical Properties: Includes indicators such as strength, breathability, and softness

| Type | Characteristics | Applicable Scenarios |

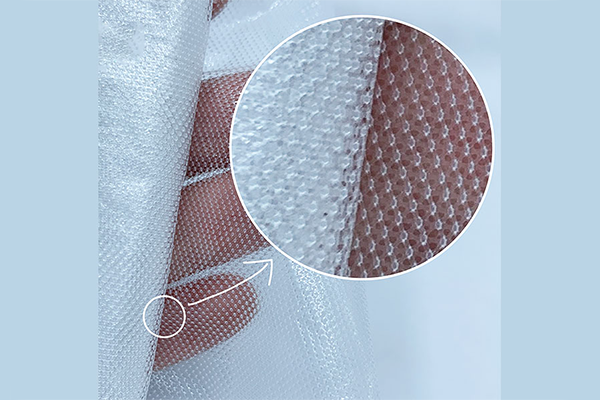

| Spunbond Nonwoven Fabric | High Strength, Low Cost | Surgical Gowns, Bed Sheets |

| Meltblown Nonwoven Fabric | Ultrafine Fiber, High Filtration | Masks, Filtration Materials |

| Spunlace Nonwoven Fabric | Soft, Lint-Free | Wound Dressings, Wipes |

The certification process typically takes 6-12 months and includes multiple stages such as material testing, clinical evaluation, and factory inspection. Our company invests substantial resources annually to maintain these certification standards.

Traditional medical gauze can no longer meet modern healthcare demands. New materials and technologies are transforming medical scenes.New types of medical fabrics have developed various functions such as antibacterial, healing promotion, and sensing. For example, the chitosan medical dressings developed by Guangdong Huiming have natural antibacterial properties, promote wound healing, and reduce the frequency of dressing changes.

Smart Monitoring Functions: Fabrics with embedded sensors can monitor wound conditions in real-time

Drug Release Technology: Fabrics can continuously release medication to enhance treatment effects

Eco-friendly and Degradable: Using materials like PLA to reduce medical waste

Personalized Design: Customizing shapes and functions according to different body parts and needs

These innovations not only improve medical outcomes but also significantly reduce the workload of healthcare professionals. Especially in chronic wound care, functional dressings have shown remarkable advantages.

Medical procurement is critical to patient safety and institutional reputation. Choosing the wrong supplier can lead to serious issues.

A high-quality medical fabric supplier should have certification credentials, research and development capabilities, and consistent quality. Guangdong Huiming, with 30 years of industry experience and over 200 patented technologies, provides products and services to more than 500 medical institutions worldwide.

When selecting a supplier, consider the following factors:

Certification Credentials: Must have FDA/ISO certifications.

Production Capacity: Can monthly output meet demand?

R&D Investment: Does the supplier have continuous innovation capabilities?

Quality Control: Full-process control from raw materials to finished products.

Case Studies: Which well-known medical institutions have they served?

Focusing only on price and not quality.

Ignoring product compatibility.

Overlooking the supplier's sustainability capabilities.

Neglecting after-sales service and technical support.

Ensures supply stability.

Provides better technical support.

Offers opportunities to participate in new product development.

Typically results in more competitive pricing.

Medical fabrics are critical to healthcare quality and patient safety, making the selection of high-quality certified products essential. With 30 years of professional experience, Guangdong Huiming provides safe and reliable medical fabric solutions for healthcare institutions.