Filtration Efficiency: Our product characterized by high filtration efficiency with low airflow resistance. Higher capture rate for fine particles (down to 0.3μm) with advanced fiber technology, exceeding industry standards.

Multi-functional Treatments: It can be subjected to functional treatments such as antibacterial, fireproof, oil-resistant, anti-static, waterproof, and odor-removing and so on.

Sustainability: Made from recycled or biodegradable materials, lowering environmental impact vs. traditional filters.

Breathability: Optimized pore design balancing low resistance with high airflow, enhancing equipment performance.

Multi-field Applications: Our air filter cotton can be applied in multiple industries, including medical aesthetics, household, medical, industrial and other fields.

Customization: Tailored dimensions and specifications for precise equipment compatibility.

How to Select Appropriate Filter Media for Medical Equipment (e.g., Ventilators, Oxygen Concentrators) to Achieve High Filtration Efficiency and Low Airflow Resistance?

I. Core Material Selection: Balancing Efficiency and Low Resistance

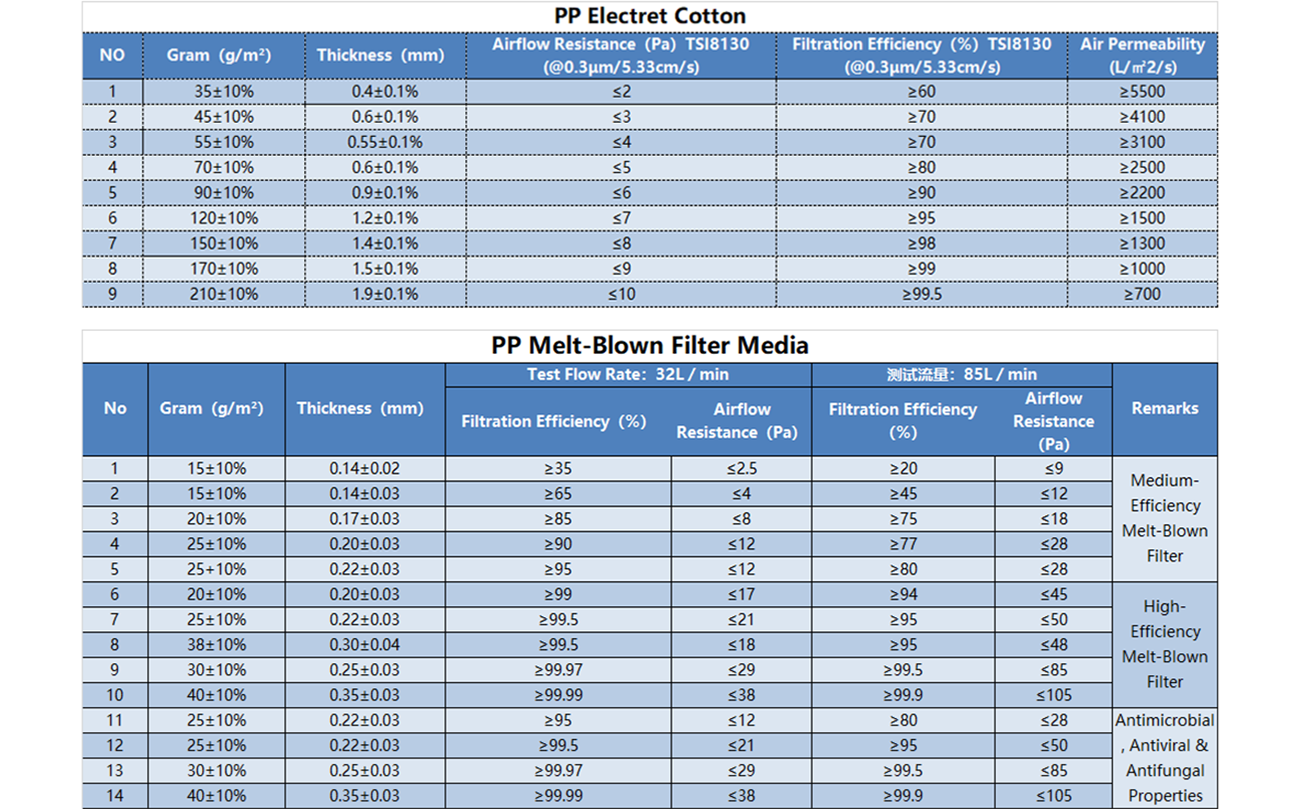

PP Melt-Blown Filter Media

Utilizes an electrostatic charging (electret treatment) process, achieving >99% filtration efficiency for particles ≥0.3μm (e.g., bacteria, droplets). However, it exhibits a relatively high initial resistance (>20 Pa).

PP Electret Cotton (Triboelectric PP Media)

Employs a triboelectric charging process, delivering >99.99% filtration efficiency for particles ≥0.3μm (e.g., bacteria, droplets). Maintains a low initial resistance (15-30 Pa), achieving an optimal balance of high efficiency and low airflow resistance.

II. Technical Solutions for Optimizing Low Resistance Design

Expand the filtration area by employing pleated filter cartridges or increasing the pleat depth of the filter media. This design significantly reduces airflow velocity by 50%, resulting in a 30%-40% reduction in airflow resistance.